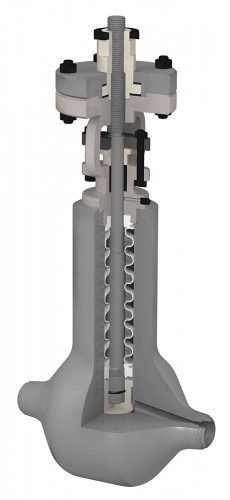

Bellows Seal

for Nuclear Power Generation

Valves used in the primary heat transport system of nuclear power plants are designed in accordance with ASME Boiler And Pressure Vessel Code, Section III, Subsection NB. They have to answer to three major technical requirements: tightness of sealing system to prevent radioactive fluid leakages to the ambient, construction able to withstand earthquake loads, construction able to pass normally required endurance tests at service condition.

FLUITEK ORSENIGO VALVES provides bellows seal globe valves, ASME/ANSI classes 600#, 900# and 1500#, materials low temperature carbon steels, austenitic stainless steels, nickel alloys, sizes ranging from 3/4” to 8” nominal size.

FLUITEK ORSENIGO VALVES design has considered and applied the following principles:

- eliminate the use of castings for pressure containing parts

- eliminate the use of strength welds, using threaded and seal welded connections where needed

- use of a very compact and geometrically homogeneous design, reducing stress concentration points introduction of a system (see separate presentation) allowing verification in service of the integrity of the bellows and, at the same time, verification of the sealing capacity of the secondary stem sealing system.

The ability of submitting production samples to endurance tests (e.g. cycling to failure at pressure and temperature conditions), to demonstrate conformity with the guaranteed minimum cycle life required, is available.

The verification of the design in relation to the ability of withstanding earthquake loads is done with the use of a shake table and operating base earthquake details.