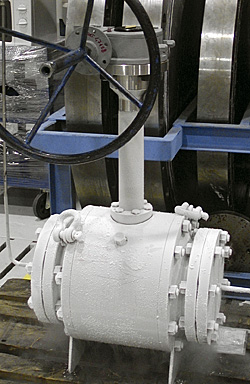

Cryogenic Service

Almost all Fluitek Orsenigo Ball Valve types can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to -196°C. If required by the customer, specific Cryogenic Tests are performed to verify the behavior of production valves in terms of valve torque, sealing capability, emissions vs the ambient.

Body construction can be two or three pieces, forged or cast. Valve design can be either Floating Type or Trunnion Type. Body and trim materials are austenitic SS, because of their ductility at low temperatures. Cryogenic Valves can be soft seated (PCTFE) or metal-to-metal seated. Valve static and dynamic seals are lip-seals PTFE based, due to the fact that PTFE material is suitable to cryogenic conditions. These seals are spring self-energized but in service are also pressure-energized by line fluid. Anti blow-out stem warrants high safety during operation and maintenance activities.

Main reference codes:

- Valve Design in accordance with API 6D / ASME B16.34, but comply also to the additional requirements prescribed by BS6364 or Customer Specifications for Cryogenic Service.

- Antistatic design as per API 6D and ISO 17292.

- Valve ends are normally flanged (RF, FF, MF or FF, RTJ), according to ASME B16.5. Other valve ends available on request.

- Cryogenic stem extension length in accordance with BS6364 or Customer Specifications.

- Fire Safe according to BS6755 / API 6FA / API 607, since each sealing point is provided by a secondary fire-safe seal in graphite. Valve soft seats also are provided with secondary metal-to-metal seal in case of fire.

Valves in Cryogenic service can be manual operated (lever or gearbox depending on valve size), but also equipped with an actuator (electric, pneumatic, hydraulic).